Every dairy has a vested economic interest in reducing feed shrink. "Feed wastage occurs on-farm in four primary manners," noted Rick Grant with the Miner Institute, at the American Dairy Science Association's Dairy Feed Efficiency Discover Conference. These inefficiency factors include:

Grant also highlighted commodity losses due to differences in storage. The loss differential between uncovered open piles, covered three-sided bays and closed bins can be seen in the chart below.

On a whole-farm basis, our goal should be to maximize the efficiency of feed use for productive purposes and minimize waste. We have progress to make in controlling shrink.

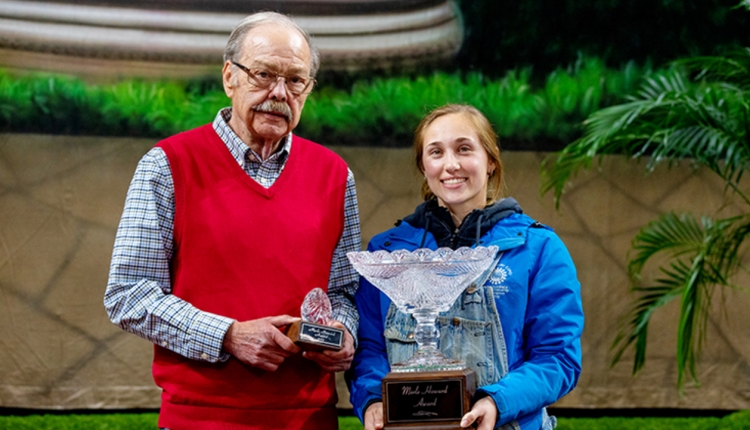

The author is an associate editor and an animal science graduate of Cornell University. Smith covers feeding, milk quality and heads up the World Dairy Expo Supplement. She grew up on a Medina, N.Y., dairy, and interned at a 1,700-cow western New York dairy, a large New York calf and heifer farm, and studied in New Zealand for one semester.

- Harvest, delivery and storage: excessive dry matter or nutrient losses from wind, precipitation, spillage or feed predation

- Mixing of diets: inconsistent nutrient delivery due to TMR mixer condition, over or under filling and mixing time

- Feed-out of diets: feedbunk loss and feed refusal amounts

- Consumption of diets: consequences of too much or too little access to feed

- Haycrop silage: 17 to 64 percent

- Corn silage: 12 to 23 percent

Grant also highlighted commodity losses due to differences in storage. The loss differential between uncovered open piles, covered three-sided bays and closed bins can be seen in the chart below.

| Feed loss in different storage structures (Kertz, 1998) | |||

|---|---|---|---|

| Ingredient | |||

| Whole cottonseed | |||

| Distillers, dry | |||

| Distillers, wet | |||

| Dry grains, typical | |||

| Alfalfa, chopped | |||

On a whole-farm basis, our goal should be to maximize the efficiency of feed use for productive purposes and minimize waste. We have progress to make in controlling shrink.

The author is an associate editor and an animal science graduate of Cornell University. Smith covers feeding, milk quality and heads up the World Dairy Expo Supplement. She grew up on a Medina, N.Y., dairy, and interned at a 1,700-cow western New York dairy, a large New York calf and heifer farm, and studied in New Zealand for one semester.