The author is an extension dairy specialist at the University of Illinois, Champaign-Urbana.

You need to remain vigilant as warmer spring weather can cause shelled corn to deteriorate in bins and other storage units. With the late fall harvest and need to dry corn rapidly, shelled corn may not dry enough in bins. This can lead to heating, mold growth, and mycotoxin buildup. The following questions and answers may avoid problems this spring.

What moisture level in stored shelled corn can lead to problems? Shelled corn over 14 percent moisture can heat and allow for mold growth. Turning on fans to move air may reduce the risk. If corn fines (broken corn pieces and small kernels) have been removed prior to storage, you may expect fewer problems.

Is high-moisture shelled corn at risk? If the moisture content of high- moisture shelled corn is correct for your storage unit (25 to 28 percent moisture for oxygen-limiting units, 28 to 32 percent for conventional silos, and 30 to 35 percent for bags or bunker storage), corn should be stable if the pH of the fermented shelled corn is under 4.5. Removal rates from storage may need to be bumped up to keep the face of the high-moisture corn fresh and avoid secondary fermentation (mold and yeast development and heating). You may need a removal rate of greater than 6 inches per day from the surface to keep wet corn stable prior to feeding. If your wet corn was snaplage (cob, husk, and some plant parts) or high-moisture ear corn, moisture levels should be higher to ensure optimal fermentation.

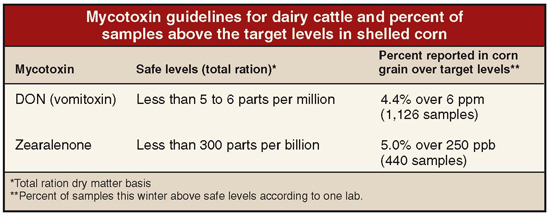

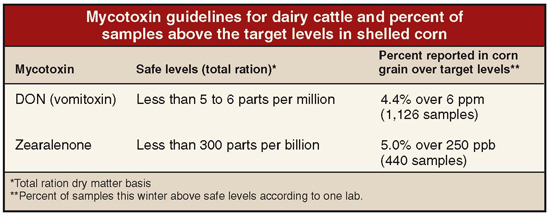

What levels of mycotoxins can be a concern? Mycotoxin risk levels for dairy cattle are listed in the table. (They are expressed on a total ration dry matter basis . . . not just for corn.) Results from a commercial Wisconsin lab indicate the percent of samples checked this year that were over the safe levels in the table. Other mycotoxins such as aflatoxin and T2 have not been reported as a field problem at this point. Vomitoxin is a "marker" mycotoxin indicating other mycotoxins may be present.

What signs of mycotoxin risks can be monitored in my herd?

1. Look for rumen disorders and reduced microbial digestion (cud chewing reduced, higher milk urea nitrogen levels, and variable feed intake).

2. See if there's looser fecal discharges (manure scores under 3).

3. You may see reduced dry matter intake (drop in 1 to 2 pounds per cow per day).

4. Watch for lower milk yields or component levels as dry matter intake declines.

What other management factors could be considered?

• Watch the quality of your shelled corn. Look for signs of heating, mold development, and damaged corn kernels.

• Testing for mycotoxins can be expensive and misleading. Getting a representative sample is difficult.

• Adding a mycotoxin-tested flow agent can reduce the impact of toxins. Check with your feed or ingredient supplier to be sure their product will be effective on vomitoxin (also called DON) which is the most common mycotoxin. A commercial flow agent (binder) containing yeast cell wall extracts or MOS (mannan oligosaccharide) products are recommended.

• Young stock and pregnant cattle are at higher risk, while steers can tolerate higher levels.

• Distillers grains produced from ethanol production can have toxin levels two to three times higher than the level found in the original corn used. Your supplier should have test results on their distillers grains.

• If propionic acid was added at ensiling, be sure the level was adequate to maintain the desired pH and prevention of heating when warm weather raises the temperature of the wet corn.

Click here to return to the Crops & Forages E-Sources

100325_228

You need to remain vigilant as warmer spring weather can cause shelled corn to deteriorate in bins and other storage units. With the late fall harvest and need to dry corn rapidly, shelled corn may not dry enough in bins. This can lead to heating, mold growth, and mycotoxin buildup. The following questions and answers may avoid problems this spring.

What moisture level in stored shelled corn can lead to problems? Shelled corn over 14 percent moisture can heat and allow for mold growth. Turning on fans to move air may reduce the risk. If corn fines (broken corn pieces and small kernels) have been removed prior to storage, you may expect fewer problems.

Is high-moisture shelled corn at risk? If the moisture content of high- moisture shelled corn is correct for your storage unit (25 to 28 percent moisture for oxygen-limiting units, 28 to 32 percent for conventional silos, and 30 to 35 percent for bags or bunker storage), corn should be stable if the pH of the fermented shelled corn is under 4.5. Removal rates from storage may need to be bumped up to keep the face of the high-moisture corn fresh and avoid secondary fermentation (mold and yeast development and heating). You may need a removal rate of greater than 6 inches per day from the surface to keep wet corn stable prior to feeding. If your wet corn was snaplage (cob, husk, and some plant parts) or high-moisture ear corn, moisture levels should be higher to ensure optimal fermentation.

What levels of mycotoxins can be a concern? Mycotoxin risk levels for dairy cattle are listed in the table. (They are expressed on a total ration dry matter basis . . . not just for corn.) Results from a commercial Wisconsin lab indicate the percent of samples checked this year that were over the safe levels in the table. Other mycotoxins such as aflatoxin and T2 have not been reported as a field problem at this point. Vomitoxin is a "marker" mycotoxin indicating other mycotoxins may be present.

What signs of mycotoxin risks can be monitored in my herd?

1. Look for rumen disorders and reduced microbial digestion (cud chewing reduced, higher milk urea nitrogen levels, and variable feed intake).

2. See if there's looser fecal discharges (manure scores under 3).

3. You may see reduced dry matter intake (drop in 1 to 2 pounds per cow per day).

4. Watch for lower milk yields or component levels as dry matter intake declines.

What other management factors could be considered?

• Watch the quality of your shelled corn. Look for signs of heating, mold development, and damaged corn kernels.

• Testing for mycotoxins can be expensive and misleading. Getting a representative sample is difficult.

• Adding a mycotoxin-tested flow agent can reduce the impact of toxins. Check with your feed or ingredient supplier to be sure their product will be effective on vomitoxin (also called DON) which is the most common mycotoxin. A commercial flow agent (binder) containing yeast cell wall extracts or MOS (mannan oligosaccharide) products are recommended.

• Young stock and pregnant cattle are at higher risk, while steers can tolerate higher levels.

• Distillers grains produced from ethanol production can have toxin levels two to three times higher than the level found in the original corn used. Your supplier should have test results on their distillers grains.

• If propionic acid was added at ensiling, be sure the level was adequate to maintain the desired pH and prevention of heating when warm weather raises the temperature of the wet corn.

100325_228